Aluminum sheet with a marble grain finish.

EN

Aluminum Honeycomb Panel Technical Parameters | |||||

| ASTM | Unit | 10mm | 15mm | 20mm | |

| Unit Theoretical Weight | kg/m² | 5.4 | 5.6 | 5.75 | |

| Tensile Strength | E8 | N/mm | 806 | 598 | 455 |

| Endurance | E8 | N/mm² | 531 | 405 | 279 |

| Elongate | E8 | % | 1.2 | 1.4 | 17 |

| Flexural Rigidity | C393 | X10⁶N .mm² | 8.03 | 15.4 | 38.44 |

| Flexural Elasticity | N/mm² | 50000 | 40600 | 38.44 | |

| Temperature Elongation Is Taught | D696 | 0.24 | 0.24 | 0.24 | |

| Thermal Conductivity | D976 | X10-⁶N/℃ | 0.23 | 0.19 | 0.15 |

| Thermal Deformation Mud Degree | D648 | ℃ | 200 | 200 | 200 |

| Bond Strength | C297 | N/mm² | 12 | 12 | |

| Flatness of the Board | The maximum deviation is 1mm/M. | ||||

| Combustion-Supporting Property | on-combustible, in line with the relevant fire rating standard | ||||

| Sound Insulation Property | 0-3dB depending on the mounting Angle of the panel | ||||

Aluminum Honeycomb Panel Specifications and Mechanical Properties | |||||||||

| Specification | Thick H (mm) | Panel T1 (mm) | Background T2 (mm) | Honeycomb Core T (mm) | Width (mm) | Length (mm) | Specific Gravity (kg/m²) | Rigidity (kN/mm²) | Sectional Film Weight (cg³/m) |

| M06 | 6 | 0.6 | 0.5 | 12-19 | 250-1500 | 600-4500 | 4.8 | 0.71 | 2.5 |

| M10 | 10 | 0.8 | 0.7 | 12-19 | 5.3 | 2.49 | 4.5 | ||

| M15 | 15 | 0.8-1.0 | 0.8 | 12-19 | 7 | 7.55 | 14 | ||

| M20 | 20 | 1.0 | 0.8 | 12-19 | 7.4 | 13.9 | 19 | ||

| M25 | 25 | 1.0 | 0.8 | 12-19 | 7.8 | 22.17 | 24 | ||

Aluminum sheet with a marble grain finish.

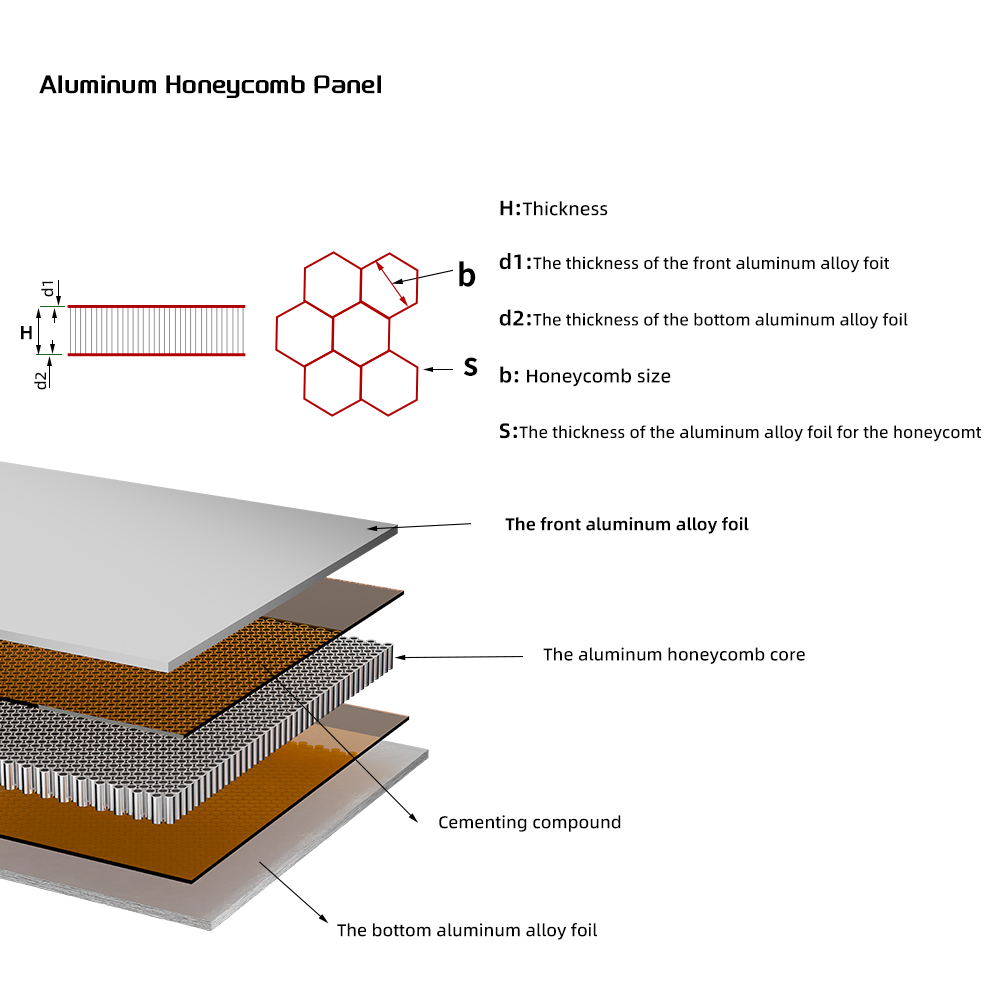

Aluminum honeycomb structure.

High-quality marble grain finish achieved through advanced printing or lamination techniques.

Typically ranges from 6mm to 50mm, depending on the application.

Customizable to meet specific project requirements.

Significantly lighter than solid marble due to the honeycomb core.

Used in various architectural features such as columns, soffits, and other design elements to add elegance.

Used for building facades to achieve a sophisticated marble appearance with enhanced durability.

Applied in wall panels, ceilings, and partitions for a luxurious and modern interior.

Utilized in the construction of lightweight, durable furniture with a marble-like finish.

Ideal for doors that require a high-end marble look without the weight and maintenance issues of real marble.

Employed in commercial signs and display panels where a marble finish is desired.