EN

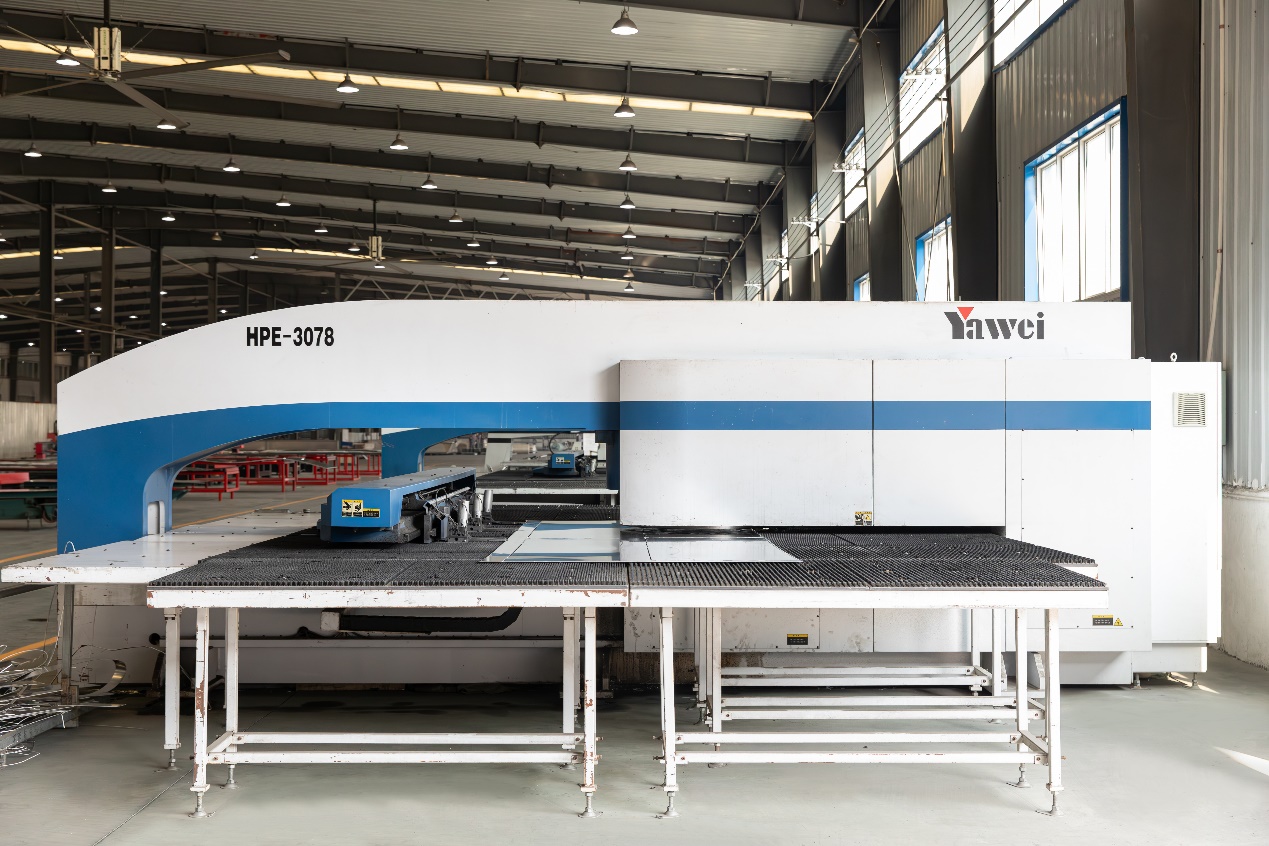

The first step: Cutting the raw material of aluminum plate into the size required by the processing designs through the numerical control equipment.

The second step: Cutting holes out on the aluminum plate according to the requirements of the drawing to facilitate subsequent assembly and installation of corner codes.

The third step: Bending, Fold the aluminum plate into a rounded corner or right Angle.

The fourth step: Welding, After the proper angle is bent, the aluminum plate's angle needs to be soldered, and the aluminum plate is basically processed and formed at this step.

The fifth step: grinding treatment, The burrs on the edges and corners of the aluminum plate are removed to make the surface of the aluminum plate more flat and smooth.

The sixth step: Assemble, Install reinforcing bars, seed nails, corner codes and etc, To prevent the deformation of aluminum plate and facilitate the installation of aluminum plate.

The seventh step: polishing treatment, the surface of the aluminum veneer is polished to a certain roughness, which is convenient for subsequent surface processing and enhances the adhesion of the

The eighth step: Through high-performance static sprayer or high-pressure sprayer spray powder coating to the surface of the aluminum sheet, under the effect of static, the powder will uniformly adhere to the aluminum sheet surface, forming a powder-shaped coating, then placed in the high-temperature furnace, so that powder melted, flattened, solidified, then aluminum plate surface treatment process is completed.