Email:

info@mritoppanel.com

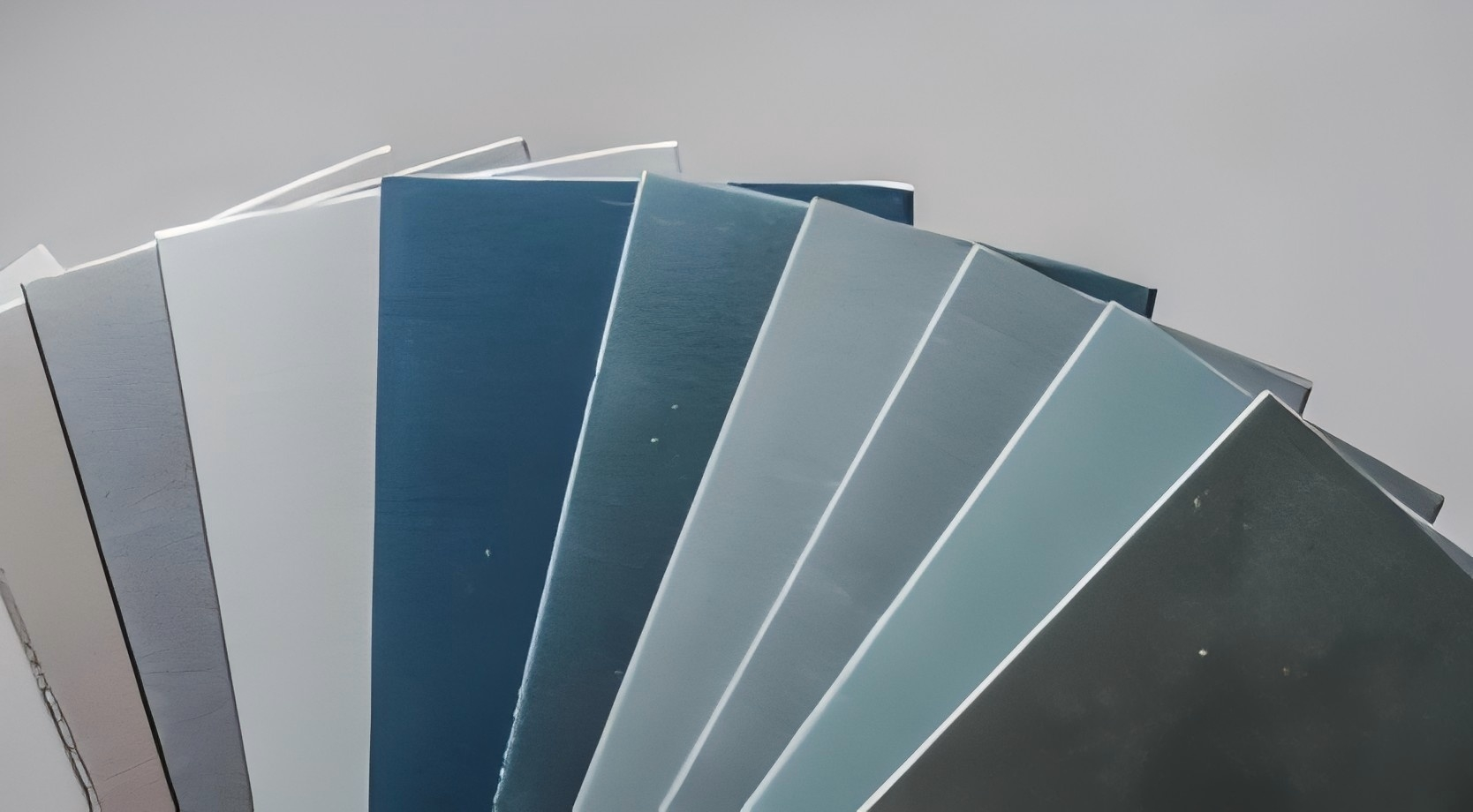

PVDF coating, made of fluorine carbon resin, is solidified into a dry film with super-weather resistance. After 2-3 coats and baking, the warranty could reach 15–20 years for exterior use.

Discover our selection of surfaces and colors, customized you need.